Automatic Portable Liquid Samplers

Model: PVS-C; Portable Composite

Model: PVS-D; Portable Discrete

Operation

Southwells Sirco brand portable samplers incorporate our patented vacuum/compressor sampling system. Sample fluid travel is limited to the intake hose, metering chamber and discharge hose, eliminating sources of cross-sample contamination such as pumps, valves and distribution plates. Repeatable sample volumes are obtained by accurate volumetric measurement of each sample, while rapid transport velocities ensure representative concentrations of solids in the sample fluid.

Rapid Sample Transport Velocities

The Southwell sampling system maintains sample transport velocities through a 3/8 ID intake hose in excess of 3 ft/s for sample lifts up to 20 ft. This important feature allows representative sampling of solids over high lifts without the precipitation problems associated with lower transport velocity samplers.

Sampler Controller

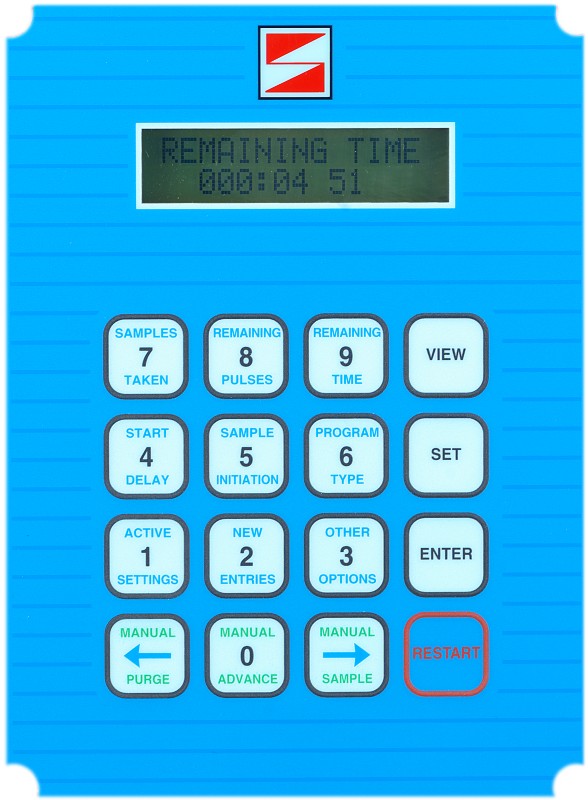

The multifunction controller is designed for versatility and simplicity. Housed in an environmentally sealed enclosure for corrosion protection, the microprocessor based controller is progammable via a 16 position keypad. All information is viewed on a 2x16 character LCD display which guides the operator through programming sequences with easily understood directions. In the event of a power failure, all program settings and information stored in the controller are maintained by an internal lithium battery.

Sampling Sequence

Sample collection begins with a high pressure air purge of the intake assembly to remove residual liquid and obstructions. Upon completion of the pre-purge cycle, the system converts to a vacuum state, drawing the sample through the intake hose, into the metering chamber until contact is made with the adjustable level sensor. The system then pressurizes, ejecting excess fluid back through the intake line until the predetermined sample volume is achieved. If the sampler, for any reason, is unable to draw a sufficient volume of fluid to obtain a sample, the operator may program the unit to automatically initiate a second attempt. Should a sample not be delivered after a second attempt, the sampler shall abort the sequence and await the next sample initiation signal. Upon two consecutive failures the sampler will suspend the sampling program until manually reset and provide a sample fault indication.

Sampler Controller

The multifunction controller is designed for versatility and simplicity. Housed in an environmentally sealed enclosure for corrosion protection, the microprocessor based controller is programmable via a 16 position keypad. All information is viewed on a 2 x 16 character LCD backlit display which guides the operator through programming sequences with easily understood directions. In the event of power failure, all program settings and information stored in the controller are maintained by an internal lithium battery.

Rapid Sample Transport Velocities

Southwells patented system maintains sample transport velocities through a 3/8 ID intake hose in excess of 3 ft/s for sample lifts up to 20 ft. This important feature allows representative sampling of large particles (unaltered or deformed) and suspended solids over high lifts without the precipitation problems associated with lower transport velocity samplers. A 5/8 ID intake system is also available for collection of even larger particles and reduced risk of intake line fouling. This larger system maintains transport velocities in excess of 3 ft/s for sample lifts up to 16 ft.

Design Specifications for PVS Series Portable Liquid Samplers

|

Start Delay Disabled no start delay Time/Day adjustable, up to 1 week in advance Pulse Count adjustable, up to 9999999 4-20mA adjustable, up to 999999 (4-20mA = 0 to 100 Pulses/Minute) External Contact momentary, 25 millisecond dry contact Level Control adjustable, up to 99 second contact duration Sample Initiation Disabled no sample initiation Interval Time adjustable up to 999 hours, 59 minutes Pulse Count adjustable up to 9999999 4-20mA adjustable, up to 999999 (4-20mA = 0 to 100 Pulses/Minute) External Contact momentary, 25 millisecond dry contact closure Program Type Composite terminate after up to 9999999 samples Multi-Composite adjustable up to 99 cycles per bottle Consecutive adjustable up to 9 bottles per cycle Daily Cycle adjustable up to 9 bottles per day (total not exceeding actual bottle count) Timed Step adjustable up to 99 hours, 59 minutes per step Clock Real Time clock real time operating system Pinch Valve Fixed normally open Purge Cycle Adjustable 1 to 99 seconds Suction cycle Variable adjusts automatically to double the input value of the purge time setting or until liquid contacts level electrode in metering chamber Direct Function Keys Manual sample Manual purge Manual bottle advance Switches Controller on/off (SPST toggle) Sample Volume Adjustable, 50cc to 500cc Sample Transport Velocity Minimum of 3 ft/s at 20 ft of lift (3/8 ID intake) Minimum of 3 ft/s at 16 ft of lift (5/8 ID intake) Metering Chamber 500cc capacity, clear acrylic, calibrated in 100ccs (opt) 500cc capacity, glass (Pyrex), calibrated in 100ccs |

Volume Control Tube 316 stainless steel Metering Chamber Level Electrode 316 stainless steel Intake Hose Nylon reinforced PVC, 3/8ID by 25 c/w sinker (opt) Nylon reinforced PVC, 5/8ID by 25 c/w sinker (opt) Teflon lined Tygon, 1/2ID by 25 c/w SS sinker Discharge Hose Latex, 3/8 ID (opt) Latex, 5/8 ID (opt) Silicone, 3/8 ID (opt) Silicone, 5/8 ID Sample Containers (composite only) (opt) 2 US gallon (8 litre) high density polyethylene (opt) 2.5 US gallon (10 litre) glass Sample Containers (discrete only) 24 x 500cc polyethylene Available displays Real time clock Process timing (elapsed, remaining) Process totals Pulse counting (internal/external) Event response (with time stamp) Multi-level descriptions Flashing prompts Automatic displays Container full (sample program complete) Fault (program not completed) Power interrupt (program resumed) Alternating time stamp Cycle(s) abandoned Enclosure Molded medium density linear polyethylene, 3 piece construction and all SS fittings. Dimensions Height 32 (810mm) Diameter 195 (495mm) Shipping weight 55 lbs (25kg) Including battery) Power 12 Vdc (from integral battery) External 12 Vdc receptacle (opt) 120 Vac/12 Vdc with integral battery charger and power cable |