|

|

SiloWeigh and

SiloWeigh.Net

|

Low cost, accurate, integrated indoor control and ..... you can install it yourself!

SiloWeigh tells you the contents of your silo

or vessel - not as an empty or full signal, or even a percentage full

signal based on a level measurement. SiloWeigh

measures the actual weight of the silo and contents to give a

true picture of the amount on hand - and it costs little more than a level

sensor.

SiloWeigh tells you the contents of your silo

or vessel - not as an empty or full signal, or even a percentage full

signal based on a level measurement. SiloWeigh

measures the actual weight of the silo and contents to give a

true picture of the amount on hand - and it costs little more than a level

sensor.

How do we achieve this breakthrough in capability, cost and convenience? SiloWeigh is the first silo weighing system to use WELDABLE STRAIN GAUGES, which attach directly to the silo legs. This method eliminates the need to lift the vessel onto load cells, making it easy to install. Unlike the more common bolt-on sensors, SiloWeigh uses high quality foil strain gauges, as used in high-accuracy load cells, to give superior stability and accuracy. We have adapted them to be spot-welded directly onto the vessel legs.

Choose the accuracy you need. SiloWeigh is temperature compensated by matching the strain gauges to the metal of the legs. We have demonstrated typical accuracies of 1 to 2% when all four legs are gauged and 2 to 5% when two legs are gauged. The exact accuracy of your installation will depend on specific silo characteristics.

All-weather. All components are carefully weatherproofed and you can set up the display system in a convenient indoor location.

Digital bar-graph indicator for each vessel shows both weight of contents and level in vessel, calibrated in either English or metric tons.

|

Download

brochure (302K) - |

Français, Deutsch, Italiano, Portugese,

Español: |

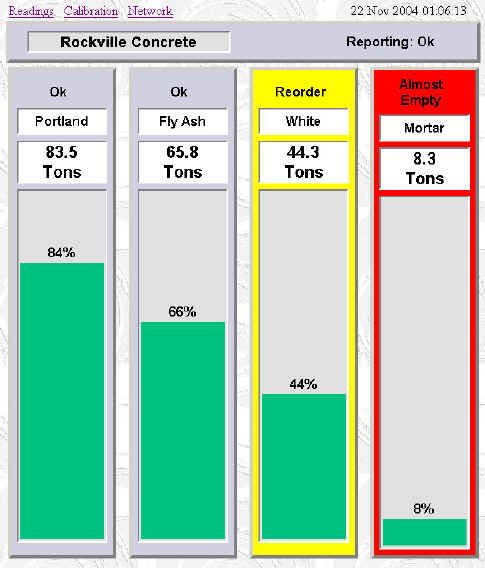

Two types of display. Choose regular SiloWeigh - the display cabinet can house up

to five bar-graph indicators to display up to five vessels at the same

time, or choose SiloWeigh.Net, the NEW network version of SiloWeigh that puts the

silo display on the desk of everyone with a computer. The SiloWeigh.Net processor is a web server, allowing

Internet pages to be generated and viewed (through an Internet browser

such as Internet Explorer) on computers throughout the company's

network. You see all your vessels shown as level gauges, plus the

actual weight in tons - see picture at right. In addition, four

types of alarm are displayed to warn of impending problems - see "White"

showing the Reorder alarm and "Mortar" showing Almost Empty. Setup

and calibration is done through similar screens, password protected for

security.

Two types of display. Choose regular SiloWeigh - the display cabinet can house up

to five bar-graph indicators to display up to five vessels at the same

time, or choose SiloWeigh.Net, the NEW network version of SiloWeigh that puts the

silo display on the desk of everyone with a computer. The SiloWeigh.Net processor is a web server, allowing

Internet pages to be generated and viewed (through an Internet browser

such as Internet Explorer) on computers throughout the company's

network. You see all your vessels shown as level gauges, plus the

actual weight in tons - see picture at right. In addition, four

types of alarm are displayed to warn of impending problems - see "White"

showing the Reorder alarm and "Mortar" showing Almost Empty. Setup

and calibration is done through similar screens, password protected for

security.

Optional digital outputs can be wired to alarm lights and bells, while SiloWeigh.Net can accept inputs from overpressure sensors to warn of impending baghouse problems.

In addition to the silo display, the SiloWeigh.Net data can be used in your own company database or stored on the SiloWeigh.Net database, allowing your company to centralize data for all silos and all plants. View a demo by clicking www.siloweigh.net.

Install and calibrate the system yourself. We deliver a kit with complete instructions. You weld two gauges to each leg using an electrical spot welder which is rented from us on a weekly basis. All required cables are provided and are colour coded. Calibration is straightforward, using the weighed deliveries as reference.Yes, we do divided silos. Most companies cannot handle silos that are divided to store two separate materials. Regardless of the position of the partition, SiloWeigh.Net uses all four legs signals to compute the weight in each side. It's just as easy to install, just as easy to calibrate.

We are available to provide complete technical support, both during and after installation.Important features and benefits:

| SILOWEIGH | SILOWEIGH.NET |

| Bar-graph indicators in wall-mount cabinet, local viewing. | Bar-graph display on network computers, company-wide viewing. |

| Shows both level in silo and actual weight in tons. | Shows both level in silo and actual weight in tons. |

| Up to 5 vessels per system. | Up to 8 vessels per system, 4 standard vessels and one divided or 2 divided. |

| Optional 4 programmable relay alarm setpoints per vessel, based on weight values, to power alarm lights or bells. | Silo symbols change color as warning. Optional 5 programmable relay alarm setpoints per vessel, based on weight or usage rate, can be directed to up to 24 relay outputs. Up to 8 inputs can accept alarm cancel button or overpressure switches to prevent baghouse blowout. |

| Optional analog output for each vessel connects to PLCs and computer control systems. | Standard RS232 and RS485 Optomux / Modbus with optional isolated analog outputs connect to control systems. |

| Calibration, setup and service by phone or local electrician. | Calibration, setup and service locally, by phone or through Internet. |

| Local storage for up to one month ensures no data lost if communication is down. | |

| Standard on all systems, connection to SiloWeigh.Net database server via Internet stores all data and alarms for viewing through Internet. | |

| Trend graphs for choice of vessels and time period, together with alarms, via Internet, give valuable history and predict future usage. | |

| Optional Internet connection to company database or ERP system to order supplies or dispatch trucks automatically. | |

| Internet database can be customized to individual requirements for ordering, etc. | |

| Internet database allows identification of unscheduled refills (by competitive suppliers etc.). |

.

|

SiloWeigh and SiloWeigh.Net can display the weight of contents in practically any vessel. Examples are: cement, sand, aggregates, flour, grains such as corn, rice, wheat, oats, barley, mineral ores, coal, coke, chemicals, plastics, even liquids and liquified gases. The easiest application is on H-beam legs, but "O" (round) section, square, "L" and "S" sections have been gauged successfully, as well as skirted silos. The only limitations are the ability to bolt the 4" (100mm) square waterproof cover onto the surface and the available stress in the leg. The stress can be calculated by measuring the cross sectional area of the leg and dividing the maximum "live load" in the leg by the area. The calculated stress should be at least 1500 lb/sq.inch (105 kg/sq.cm). For example, a vessel holds 100 tons (200,000 lb) of cement and has 4 legs with a cross section of 12 square inches. each leg will carry a maximum live load of 200,000/4 = 50,000 lb. Dividing this by 12 gives 4166 lb/sq.in, which is safely above the limit of 1500. Note that legs that are designed for greater safety margins will have less stress and will have a lower electrical output as a result. The lower output will increase the drift in readings due to temperature changes and side loads. |

The power of the SiloWeigh.Net system is the ongoing connection to the SiloWeigh.Net database server. The client’s company database is accessible by any web browser (via passwords to ensure total security), enabling the client (cement, concrete or similar company) to see all customers’ silo levels and dispatch deliveries accordingly. End users can see their own silos’ status and order directly on-line.

| Scale-Tron’s web based database – The SiloWeigh.Net database is housed on a commercial server with professional maintenance and backup service to ensure your data is never lost, is secure from hacker attack and is available to you all the time, any time, 24 hours a day, 7 days per week. Whether you choose to link the SiloWeigh.Net database to your own company database or use SiloWeigh.Net’s services for all your needs, the SiloWeigh.Net server is your source for silo data. The single database is subdivided among all SiloWeigh.Net’s clients, each having its own passwords for access. |  |

|

In your company’s area, you have the ability to store data for your own customer companies, divisions and plants or sites. Each plant/site holds data for all its vessels, which can be displayed individually or as groups holding the same product. The data can be displayed directly as tables of data as it is received, or sorted by company, site, time and date etc. It can also be displayed in graphical form for each site, as a trend graph which can be zoomed to any time and date period. In addition to the weight data, the database holds a record of each alarm condition encountered, with time and date. |

|

|

Any or all the data is accessible by a remote database server, using TCP/IP protocol, enabling it to be combined with private company data on customers, products and orders. This allows clients to organize dispatching of deliveries or sales. Individual client areas can be customized with additional data and reports etc. Contact us for more details.

|

|

We have installed the SiloWeigh system in our concrete batching plants in Korea. We have found them easy to install and more accurate than other similar products when in use. We particularly like easy calibration and simplicity of installation. A major benefit of SiloWeigh system that we have noticed is its ability to calibrate from deliveries of material, without the need for fully emptying the silo, as is required with regular weigh scales. Congratulations on a well made product with a great future. Sincerely yours, TAESHIN CORPORATION |

See how it's done - with close up photographs

Need more information? Contact Scale-Tron - Feedback form Email: Scale-Tron

Last updated: November 22, 2004