|

|

Tech Tips |

Franšais, Deutsche, Italiana, Portugese, Espa˝ol: Translate this page automatically.

Jan 1999 - Getting proper information from water and admix meters

Does your batching computer always give exactly the

right amount of admix and water? It probably doesn't, but you'll

never know it. The big admix companies use a practice that makes their

equipment look better than it really is; as a result, you could be using

(and paying for) more admix than you think. Pre-wired admix controls are

usually wired so that the power for the meter comes from the filling valve

solenoid output on the computer. As a result, when the filling is complete

and the valve is turned off, the meter stops counting. This does not mean

that the flow of admix has stopped, however. If the flow was fast, it

probably continues for a fraction of a second before the valve closes and

this can translate into a few ounces or many millilitres in every batch.

Even worse, consider the valve that sticks in the OPEN condition, allowing

admix to flow, possibly at a much reduced rate, during bottle discharge

and all the time up to the start of the next batch. This will never be

recorded and will take an alert operator before it is spotted.

Does your batching computer always give exactly the

right amount of admix and water? It probably doesn't, but you'll

never know it. The big admix companies use a practice that makes their

equipment look better than it really is; as a result, you could be using

(and paying for) more admix than you think. Pre-wired admix controls are

usually wired so that the power for the meter comes from the filling valve

solenoid output on the computer. As a result, when the filling is complete

and the valve is turned off, the meter stops counting. This does not mean

that the flow of admix has stopped, however. If the flow was fast, it

probably continues for a fraction of a second before the valve closes and

this can translate into a few ounces or many millilitres in every batch.

Even worse, consider the valve that sticks in the OPEN condition, allowing

admix to flow, possibly at a much reduced rate, during bottle discharge

and all the time up to the start of the next batch. This will never be

recorded and will take an alert operator before it is spotted.

The solution is to re-wire the admix controller, which we do on almost every installation, to power the meter from a solid power source (see diagram). As long as the batching computer continues to monitor the meter after the valve is shut off, the errors above will be caught.

Water valves and meters should be wired in the same manner.

P.S. - Master Builders assures us that their admix systems are wired correctly; the above change is not necessary! Thanks for the feedback.

Feb 1999 - Improve jogging performance with flow control valves

Big feed gates with large operating cylinders can open

very quickly. When jogging at the end of the feed period, the objective is

to release small bursts of material with each jog. Batching computers

usually control the "open time" of the gate in steps of around 1/10

second; since it takes 1/10 to 2/10 second to start the gate moving, and

it can be full open in 3/10 second, a setting of 2/10 may drop no material

while a setting of 3/10 can drop 50lb/20kg - too much for accurate

batching. The computer's automatic tuning can try to adjust the jog time

but it will jump from 2/10 to 3/10 second and back again in succesive

batches. This is futile and will result in lost time and tolerance

errors.

Big feed gates with large operating cylinders can open

very quickly. When jogging at the end of the feed period, the objective is

to release small bursts of material with each jog. Batching computers

usually control the "open time" of the gate in steps of around 1/10

second; since it takes 1/10 to 2/10 second to start the gate moving, and

it can be full open in 3/10 second, a setting of 2/10 may drop no material

while a setting of 3/10 can drop 50lb/20kg - too much for accurate

batching. The computer's automatic tuning can try to adjust the jog time

but it will jump from 2/10 to 3/10 second and back again in succesive

batches. This is futile and will result in lost time and tolerance

errors.

The solution is to add a flow control valve in the opening direction only. When adjusted to a speed of 1 second (approximately) from closed to full open, the open time plus the size of the opening can be adjusted in small steps. Since the volume of material dropped in each jog is roughly proportional to the area under the curve (see diagram), the amount of each drop can be accurately controlled by the same 1/10 second steps. This allows the automatic tuning (assuming that your system has it) to easily adjust to the best setting.

Mar 1999 - Installing a RadarTron moisture sensor in a chute

In order for a moisture sensor such as the RadarTron to work

properly, it must have a bed of material at least 4" (10cm) thick in front

of the faceplate. Further, the material must be of a known or constant

density. In chutes, the material tends to move quickly and is suspended in

air, preventing the two conditions above from being fulfilled. The

material must be held or restricted for it to build up. This is difficult

to do without creating a stagnant bed of material which does not move,

however.

In order for a moisture sensor such as the RadarTron to work

properly, it must have a bed of material at least 4" (10cm) thick in front

of the faceplate. Further, the material must be of a known or constant

density. In chutes, the material tends to move quickly and is suspended in

air, preventing the two conditions above from being fulfilled. The

material must be held or restricted for it to build up. This is difficult

to do without creating a stagnant bed of material which does not move,

however.

A recent installation solved these problems by using a couple of tricks. The first is to channel the flow into the centre of the chute with a funnel-like channel. The second is to build a "flapper valve" which alternately holds the material and releases it, allowing fresh samples to be measured. The flapper valve is hinged, with a counterweight arranged to keep it closed until the chute is completely filled with material, when it will open and let the material out. This also prevents the blockages and build-up which could be caused by lumpy material.

Getting this arrangement to work is a little tricky and needs some special twists, which we don't have the space for here. It really does work, however, and is in regular use in controlling a drying plant for bentonite. Call, fax, register or Email for more details.

April 1999 - Checking your scale calibration

We had a situation several years ago where a concrete plant

had been making sub-standard product. It was found that the cement scale

was reading 20% too high, which caused it to weigh out too little cement

on each batch. Understandably, our customer was very upset. The fact is,

however, that the customer is responsible for checking his equipment, and

that includes scales. This was an extreme case, but it shows very clearly

what can happen when we blindly believe our instruments. Even if the

scales are checked every 6 months, things like this can happen.

We had a situation several years ago where a concrete plant

had been making sub-standard product. It was found that the cement scale

was reading 20% too high, which caused it to weigh out too little cement

on each batch. Understandably, our customer was very upset. The fact is,

however, that the customer is responsible for checking his equipment, and

that includes scales. This was an extreme case, but it shows very clearly

what can happen when we blindly believe our instruments. Even if the

scales are checked every 6 months, things like this can happen.

We recommend that batching scales be checked every week by having someone apply his body weight to each scale, while someone else reads the display. This is rough and ready, but will find gross errors quickly before much damage is done. A better way is to use our SHUNT CALIBRATOR unit, which connects to each scale in turn. It simulates a known weight, checking the complete load cell circuit as well as the indicator. This avoids the need for test weights during weekly tests, but a six monthly calibration test should still be done to meet quality plan requirements.

For more details, see our Transmitters page.

May 1999 - Improve batching performance

Does the shock of aggregate hitting the bottom

of the weigh hopper cause your scale reading to "bounce"? Do you get out

of tolerance weights as a result? Many systems exhibit this type of

performance but it is easily corrected. A piece of 6" angle, welded across

the hopper directly under each gate, will reduce the momentum of the

falling material and spread the pile of aggregate, allowing a little more

to be batched into the hopper before it touches the gate. More important,

however, it allows the scale to react instantly to the falling material.

This removes the bounce effect while shortening the response time of the

scale.

Does the shock of aggregate hitting the bottom

of the weigh hopper cause your scale reading to "bounce"? Do you get out

of tolerance weights as a result? Many systems exhibit this type of

performance but it is easily corrected. A piece of 6" angle, welded across

the hopper directly under each gate, will reduce the momentum of the

falling material and spread the pile of aggregate, allowing a little more

to be batched into the hopper before it touches the gate. More important,

however, it allows the scale to react instantly to the falling material.

This removes the bounce effect while shortening the response time of the

scale.

This is also very effective when batching small quantities of material. Without the angle, it has to fall to the bottom of the hopper before the scale can react, increasing the possibility for overshoot before the gate can close. The angle allows the system to react properly regardless of the transit distance; the gate closes normally and can also be jogged to obtain greater accuracy. Size of the angle is not critical, but it should intercept at least 50% of the flow to be effective.

June 1999 - Choice of load cells can be crucial

Many batch plant scales today are suspended from tension load cells. Usually 4, but sometimes 3 of the popular "S" type cells can support a scale hopper or conveyor. Many people installing their own equipment use these cells but do not fully understand their differences.

To do a proper job, all load cells on the same scale must have equal sensitivity or be equalized by means of a "summing box". Equal sensitivity cells are called "standardized" and have outputs balanced to within 1/4% or better. On a concrete batching scale, there is no need to balance the cells further, eliminating the need for a summing box and the lengthy adjustment procedure that accompanies it. Most models of the "S" cell are are low in cost and hence are not standardized. This makes it imperative to use a summing box and go through the "corner adjustment" procedure with test weights before the scale is accurate enough to be used. Consider this fact carefully before making your choice of load cells; the corner test might be difficult or impossible to carry out because of lack of room, danger to personnel or insufficient time.

The A.S.T. range of load cells are all standardized; this makes them ideal for use on batching scales of all types. They are also very competitive in price and do not require a summing box. Contact us for further information.

July 1999 - Can you run out of admix without knowing it?

If you use the popular types of pump and admix

meters, the answer is probably YES! Many pumps will happily pump

air, and the meter will measure it just as though it was admix. Even if

you have sight glasses, it is possible for no-one to notice it. You make

batch after batch with no admix; this can be a disaster.

Fortunately, there is an easy fix. A simple proximity

detector can be attached to the outside of the plastic admix tank,

allowing early warning of low admix level. When connected to BatchTron or

Genie-II inputs, alarm messages can be generated.

If you use the popular types of pump and admix

meters, the answer is probably YES! Many pumps will happily pump

air, and the meter will measure it just as though it was admix. Even if

you have sight glasses, it is possible for no-one to notice it. You make

batch after batch with no admix; this can be a disaster.

Fortunately, there is an easy fix. A simple proximity

detector can be attached to the outside of the plastic admix tank,

allowing early warning of low admix level. When connected to BatchTron or

Genie-II inputs, alarm messages can be generated.

We have installed these sensors in concrete plants. Call us for details.

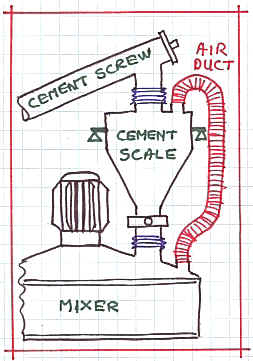

September 1999 - Cure a common cement scale problem

If you have a cement weigh hopper (or something

similar), you might find that its "empty" reading changes from when the

discharge valve is open to when it is closed. This can be severe

enough to prevent start of the next batch if the control system checks the

empty weight before starting, as it should do. The reason is almost

always an air pressure difference between the interior of the hopper and

the vessel which it feeds (typically the mixer). This can be caused

by a dust extractor attached to the mixer, aeration of the hopper (to aid

in discharge) or merely by the flow of materials in the system, which

displaces air.

If you have a cement weigh hopper (or something

similar), you might find that its "empty" reading changes from when the

discharge valve is open to when it is closed. This can be severe

enough to prevent start of the next batch if the control system checks the

empty weight before starting, as it should do. The reason is almost

always an air pressure difference between the interior of the hopper and

the vessel which it feeds (typically the mixer). This can be caused

by a dust extractor attached to the mixer, aeration of the hopper (to aid

in discharge) or merely by the flow of materials in the system, which

displaces air.

The solution is to add a bypass pipe. This can be as simple as a length of flexible plastic hose 3" or 4" in diameter, connected to the top of the cement hopper at one end and the mixer or vessel being fed at the other. This equalizes the pressure at both sides of the discharge valve as well as the feed point (see diagram), which in turn eliminates any vertical force on the load cells or scale. An important side benefit is that it provides a path for air displaced during both filling and discharge, speeding operation and eliminating another source of weight error during feeding. Any dust in this displaced air is returned to the mixer which in turn is evacuated by the dust collector, if used.

Be careful to use flexible hose (the corrugated type is best) and to secure it to the building structure to prevent it affecting normal weight readings.

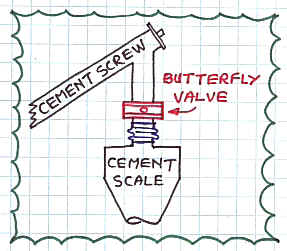

October 1999 - Butterfly valve saves cement dollars

Most older concrete plants, whether for

ready-mix or products, use screw feeders for the cementitious

materials. The feed from these feeders is not constant, however, and

has a large variation depending on the rotation of the screw

flights. After the motor is stopped, the overfeed depends on the

screw position and will vary; assuming that the batching computer

has accurately compensated for the "in-flight" material, the end weight

will be over or under the target weight because of this variation.

This forces the producer to add a little more cement than is needed on

every batch, which costs a huge amount over a year's production.

Also, excessive aeration of the cement silo, needed to improve flow, can

cause fluidization of the cement in the screw feeder which then creates an

overweight situation.

Most older concrete plants, whether for

ready-mix or products, use screw feeders for the cementitious

materials. The feed from these feeders is not constant, however, and

has a large variation depending on the rotation of the screw

flights. After the motor is stopped, the overfeed depends on the

screw position and will vary; assuming that the batching computer

has accurately compensated for the "in-flight" material, the end weight

will be over or under the target weight because of this variation.

This forces the producer to add a little more cement than is needed on

every batch, which costs a huge amount over a year's production.

Also, excessive aeration of the cement silo, needed to improve flow, can

cause fluidization of the cement in the screw feeder which then creates an

overweight situation.

Both these problems can be eliminated by adding a fast acting butterfly valve under the screw feeder exit. If the exit tube is long, it should be as close to the cement scale as possible to minimize the in-flight amount. Ensure that a very flexible sock is fitted between this valve and the scale to minimize the effect on the weight reading.

The valve operating cylinder should be actuated from a solenoid valve which is connected to the motor starter for the screw feeder. If you are worried about the valve failing to open, mount a limit switch on the valve and use it to close the circuit to the screw feeder motor starter.

The resultant material saving on most feeders averages 1/2 to 1%. Add this up over a year's production; you can probably justify a new BatchTron system with the amount you save!

November/December 1999 - Fiber bag dispenser saves labor cost

One of our lesser known products, the Fiber Bag Dispenser,

conveniently drops bags of fiber into the mixer with each batch of

concrete. The conventional method, where the operator runs up the

stairs and drops a bag by hand every time the mixer is loaded is

inconvenient, inefficient and prone to being neglected on occasion.

The bag dispenser removes these problems and guarantees a bag in every

batch.

One of our lesser known products, the Fiber Bag Dispenser,

conveniently drops bags of fiber into the mixer with each batch of

concrete. The conventional method, where the operator runs up the

stairs and drops a bag by hand every time the mixer is loaded is

inconvenient, inefficient and prone to being neglected on occasion.

The bag dispenser removes these problems and guarantees a bag in every

batch.

Operating like the potato chip bag dispensers in vending machines, the dispenser is loaded with bags at the start of operation. As each batch is dropped into the mixer, it is triggered to drop either one or several bags. When the holding tray is empty, it warns the operator to refill it again and can hold back the next batch if not filled. The standard tray size holds 15 of the usual "Grace size" bags. Options such as bag cutters and multiple bag counters are available. Call us for details and pricing.

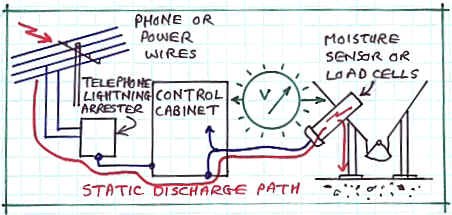

March 2001 - Protect batching system from power surges

Several end users of our products have had mysterious failures of moisture sensors and load cells. Analysis of the components show that a high voltage has broken down the insulation between the circuit board or sensor and the metal case, destroying all or part of the electronics as well as the sensor or load cell.

This is caused by a high voltage appearing on

the case of the controller, which then appears on everything inside it,

eventually finding the shortest path to ground through the offending

device. This occurs when the path from the controller to earth

ground is long. In one case, the incoming phone line had its

lightning arrester ground point connected to the controller cabinet but

there was only a thin 16 gauge ground wire from the cabinet to power

ground about 50 ft away. Static discharges (due to nearby electrical

storms and induced voltages from power lines) travelled down the phone

lines, through the cabinet ground, the moisture sensor and load cells to

the plant frame, frying the sensor and load cell in the process. A

European-style power system with power line neutral coming in through

overhead cables can be just as bad.

This is caused by a high voltage appearing on

the case of the controller, which then appears on everything inside it,

eventually finding the shortest path to ground through the offending

device. This occurs when the path from the controller to earth

ground is long. In one case, the incoming phone line had its

lightning arrester ground point connected to the controller cabinet but

there was only a thin 16 gauge ground wire from the cabinet to power

ground about 50 ft away. Static discharges (due to nearby electrical

storms and induced voltages from power lines) travelled down the phone

lines, through the cabinet ground, the moisture sensor and load cells to

the plant frame, frying the sensor and load cell in the process. A

European-style power system with power line neutral coming in through

overhead cables can be just as bad.

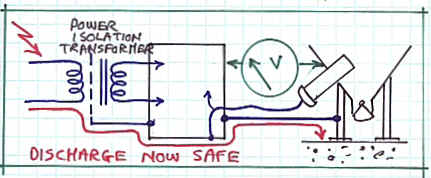

The path for the incoming surge is through the power line, power

neutral, telephone line or other overhead wire to the control

cabinet. The analog inputs for the moisture sensors and load cells

are grounded to the cabinet and conduct this surge to the moisture sensor

or load cell, where it jumps the insulation and grounds itself through the

plant's frame.  The solution is simple and effective. Connect the plant frame to the

controller cabinet with a thick (#10 gauge or 5 mm) ground cable as short

as possible. This minimizes the voltage that can appear between the

two and reduces the risk of striking through the insulation of the sensor

or load cell. We recommend that this is done on all plants, regardless of

whether they have had a problem or not. It's just good

insurance. If the problem appears to be severe, it also helps to put

an isolating transformer (equal voltage input and output) in the power

line before the controller (and before the UPS if used, since most UPSs do

not provide isolation).

The solution is simple and effective. Connect the plant frame to the

controller cabinet with a thick (#10 gauge or 5 mm) ground cable as short

as possible. This minimizes the voltage that can appear between the

two and reduces the risk of striking through the insulation of the sensor

or load cell. We recommend that this is done on all plants, regardless of

whether they have had a problem or not. It's just good

insurance. If the problem appears to be severe, it also helps to put

an isolating transformer (equal voltage input and output) in the power

line before the controller (and before the UPS if used, since most UPSs do

not provide isolation).

Much as we love the business that lightning, fires and floods bring, we appreciate that it costs your business a lot of money when it happens. You might also want to consult us on the best grounding methods if you're not sure. Most of the time we can do it without a site visit.

Need more information? Contact Scale-Tron - Feedback form Email: Scale-Tron

Last updated: November 07, 2004