New

- DLT 2.0

Differential Level Transmitter

|

|

|

DLT 2.0 Differential Level Transmitter

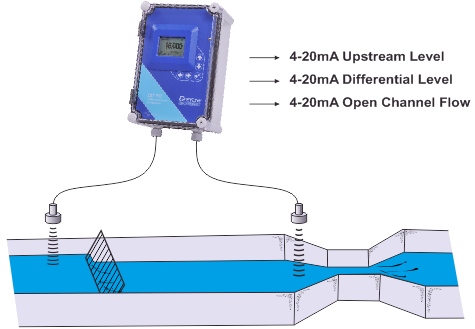

Reduce costs and simplify instrumentation at treatment plant headworks. The DLT 2.0 can measure both differential level plus flow through a flume. Install one Sensor on each side of a mechanical barscreen to continuously monitor, transmit and control level. Use the built-in control relays or 4-20mA outputs to automatically activate the barscreen rake at preset levels.

|

The DLT 2.0 is a simple solution for barscreen level control at wastewater treatment plants, pump stations and combined sewer systems. It includes two non-contacting ultrasonic sensors to measure level. With sensors positioned above a channel, up and downstream from the barscreen, the DLT 2.0 can display and transmit differential level. The downstream sensor can also be installed above a flume or weir to measure and totalize open channel flow. Three 4-20mA outputs are configured to transmit upstream level, downstream level (or flow) and differential level. Built-in relays can be calibrated for level control, differential level control or open channel flow. |

|

Other DLT 2.0 applications include two-tank inventory where you can monitor level in two tanks with one instrument. The DLT 2.0 will alternate display of level in both tanks plus transmit 4-20mA outputs. Use the built-in relays to activate alarms or level controls. This versatile dual-sensor instrument can also be configured as a submergence alarm for Parshall flumes.

|

For Single Sensor Level Monitoring and Control... Consider the Greyline SLT32 Level & Flow Monitor for tank level and volume measurement or for open channel flow through flumes and weirs. The Greyline SLT32 includes 3 relays, a 4-digit LCD display and an isolated 4-20mA output. |